Team project • 5 months • Prototype

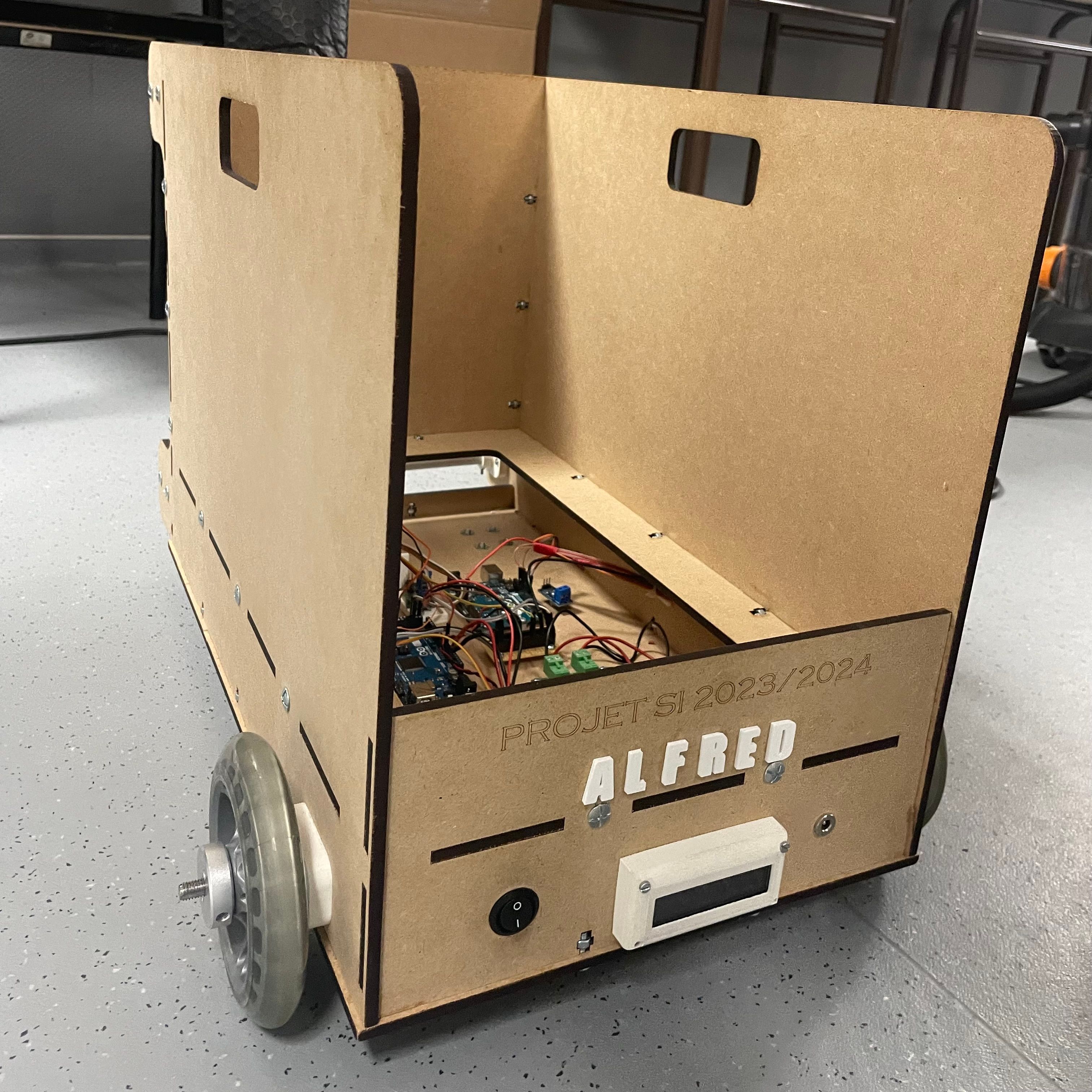

ALFRED — Smart Shopping Cart Companion

A motorized rolling cart designed to follow a customer in a supermarket, helping people with reduced mobility carry groceries without pulling or lifting heavy loads.

Context & Problem

In supermarkets, carrying or pulling a basket can be difficult for people with reduced mobility. ALFRED was built to reduce physical effort and improve autonomy during shopping, while staying safe in dynamic environments (aisles, other customers, obstacles).

Goal

Create a rolling cart that reliably follows a user and avoids obstacles, with a simple interface and a robust power system for real-world usage.

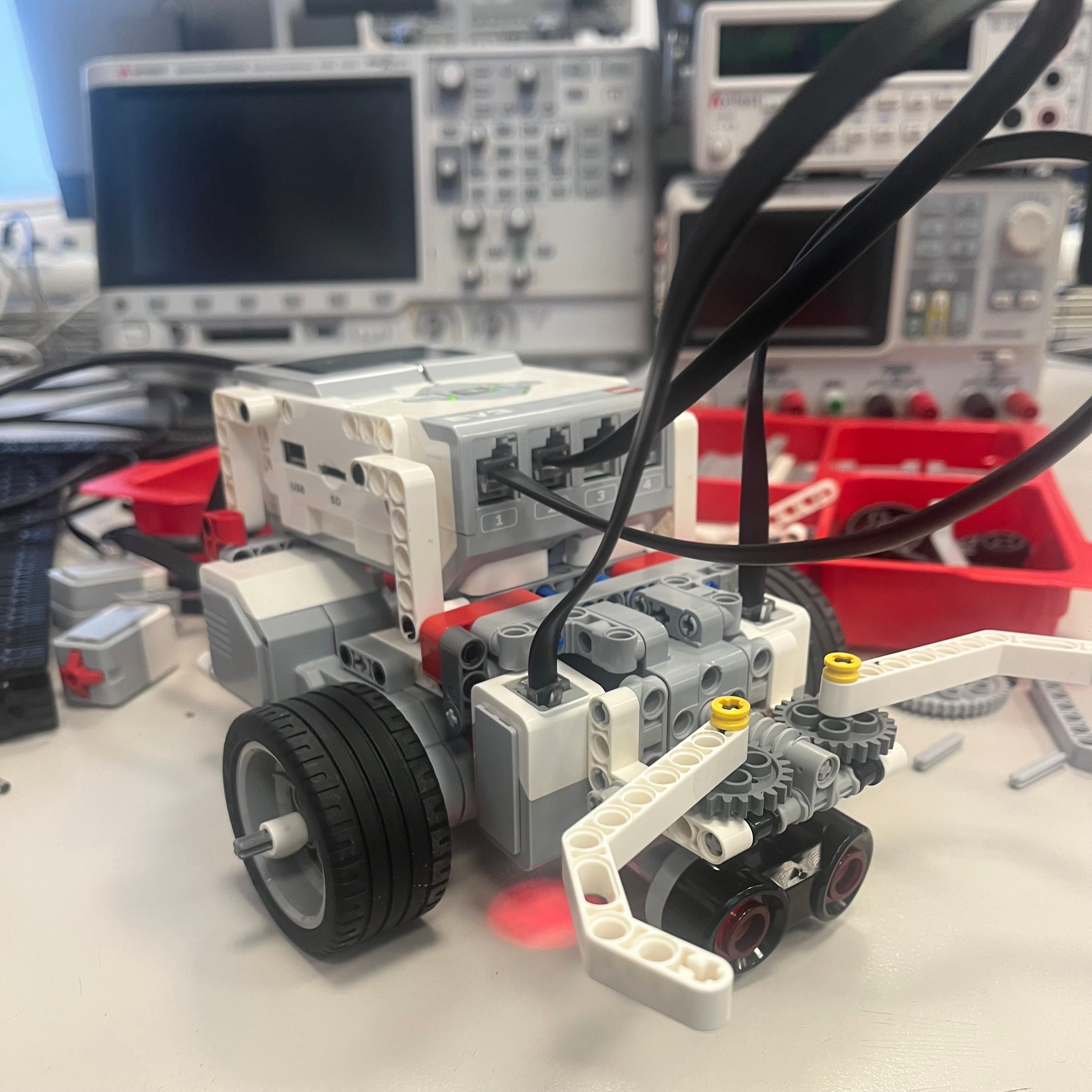

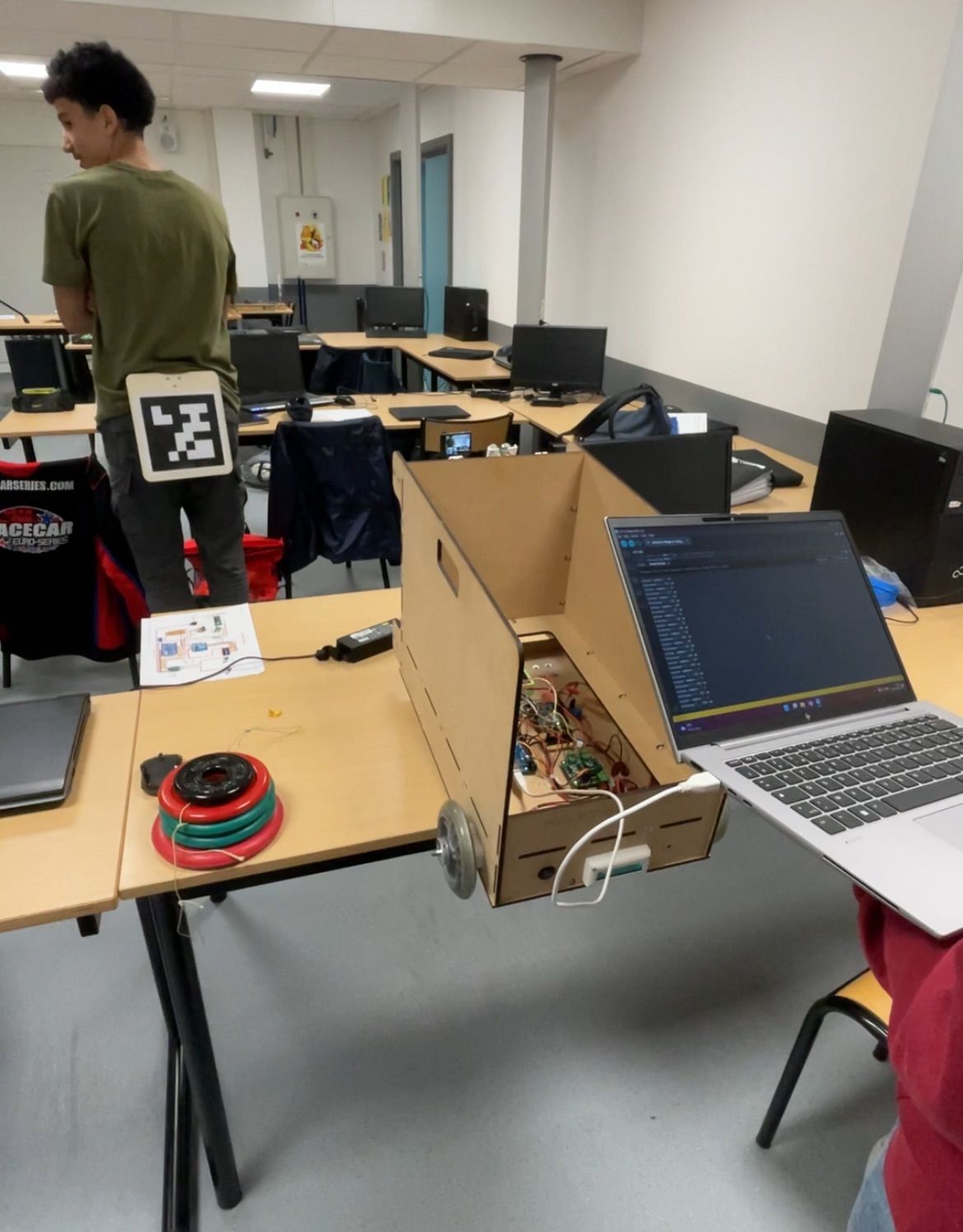

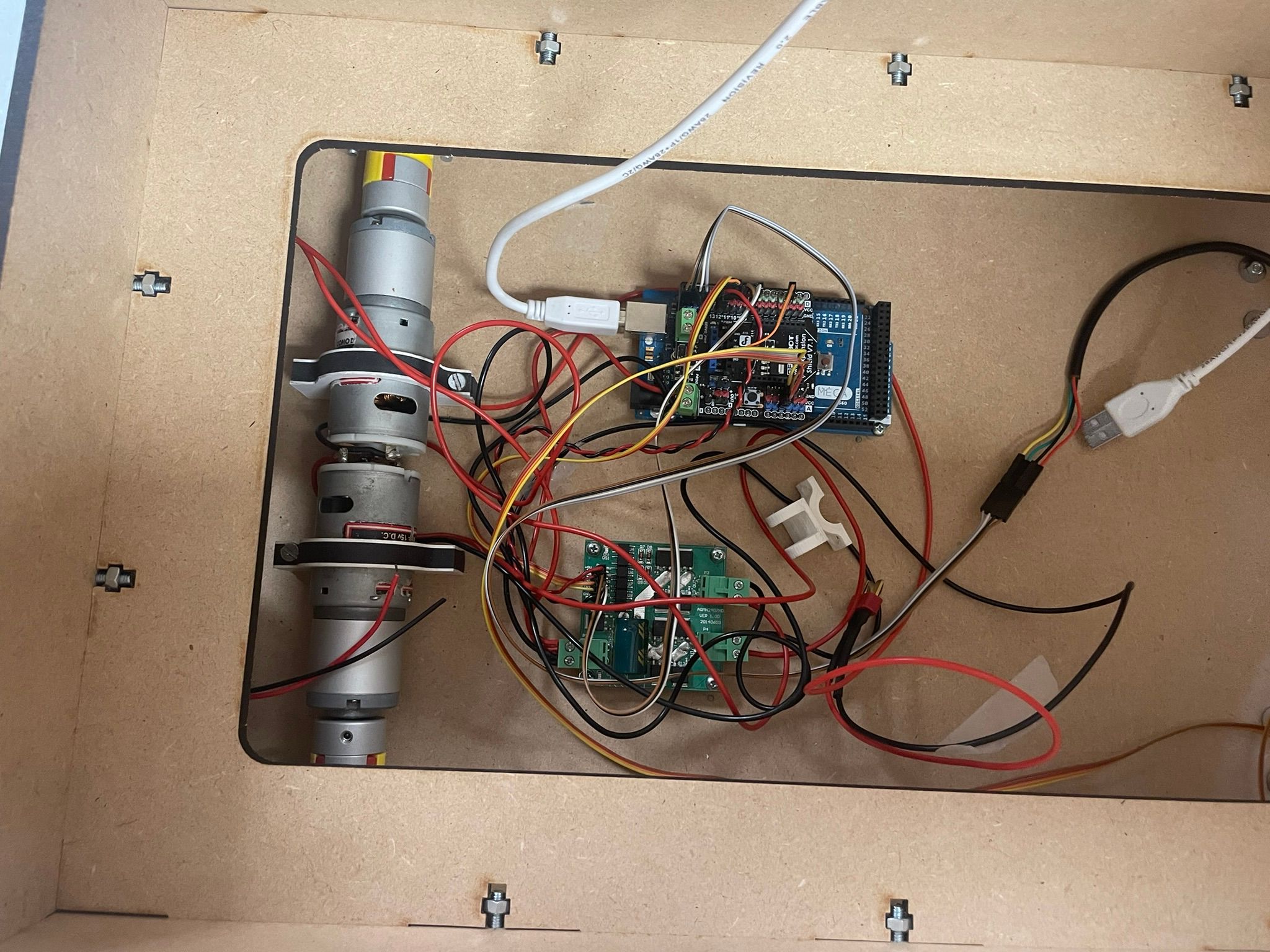

Prototyping overview — Motor testing using QR code recognition

Team & Responsibilities

Théo Gertz

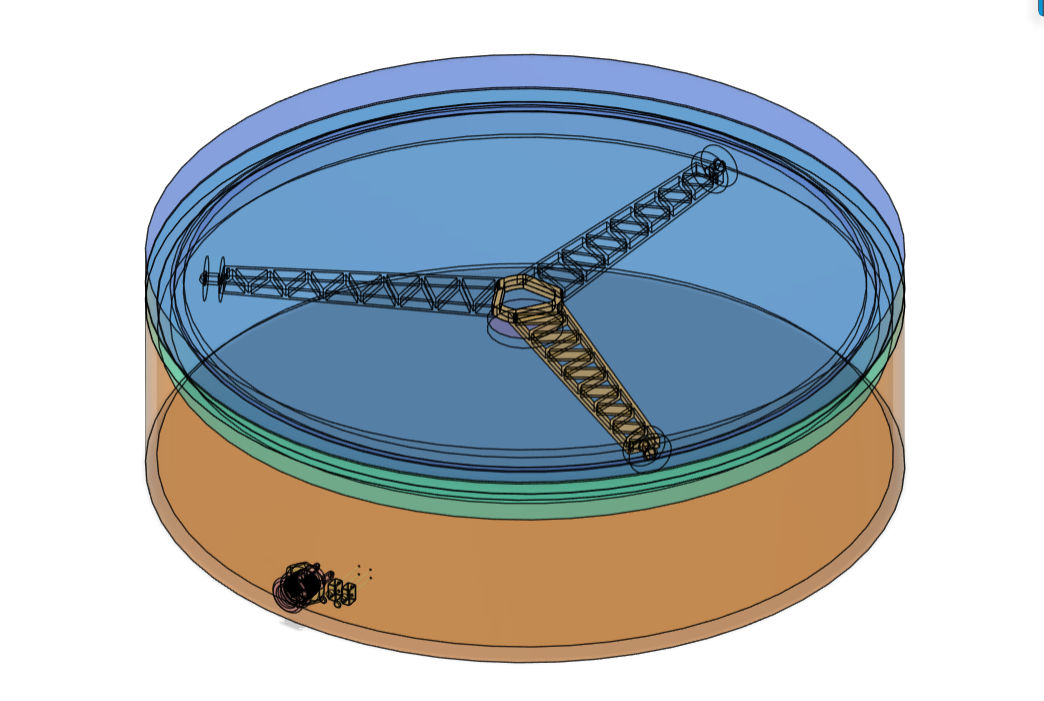

- Mechanical design & conception

- Support on cart programming

Sacha Bruckert

- Motorization & sensors selection

- Programming (motors / sensors)

Yassir Bellahcen

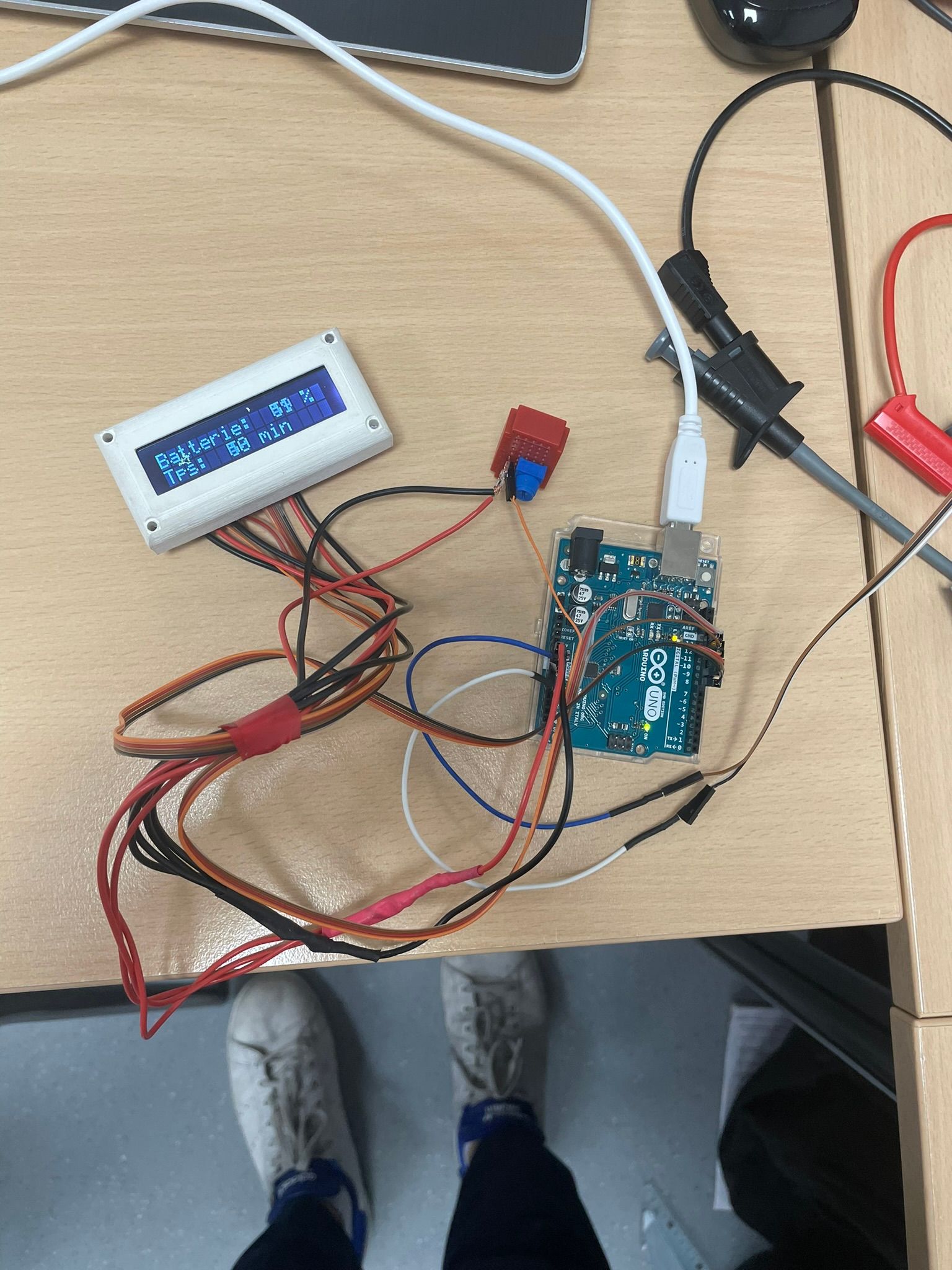

- User information module (LED, LCD)

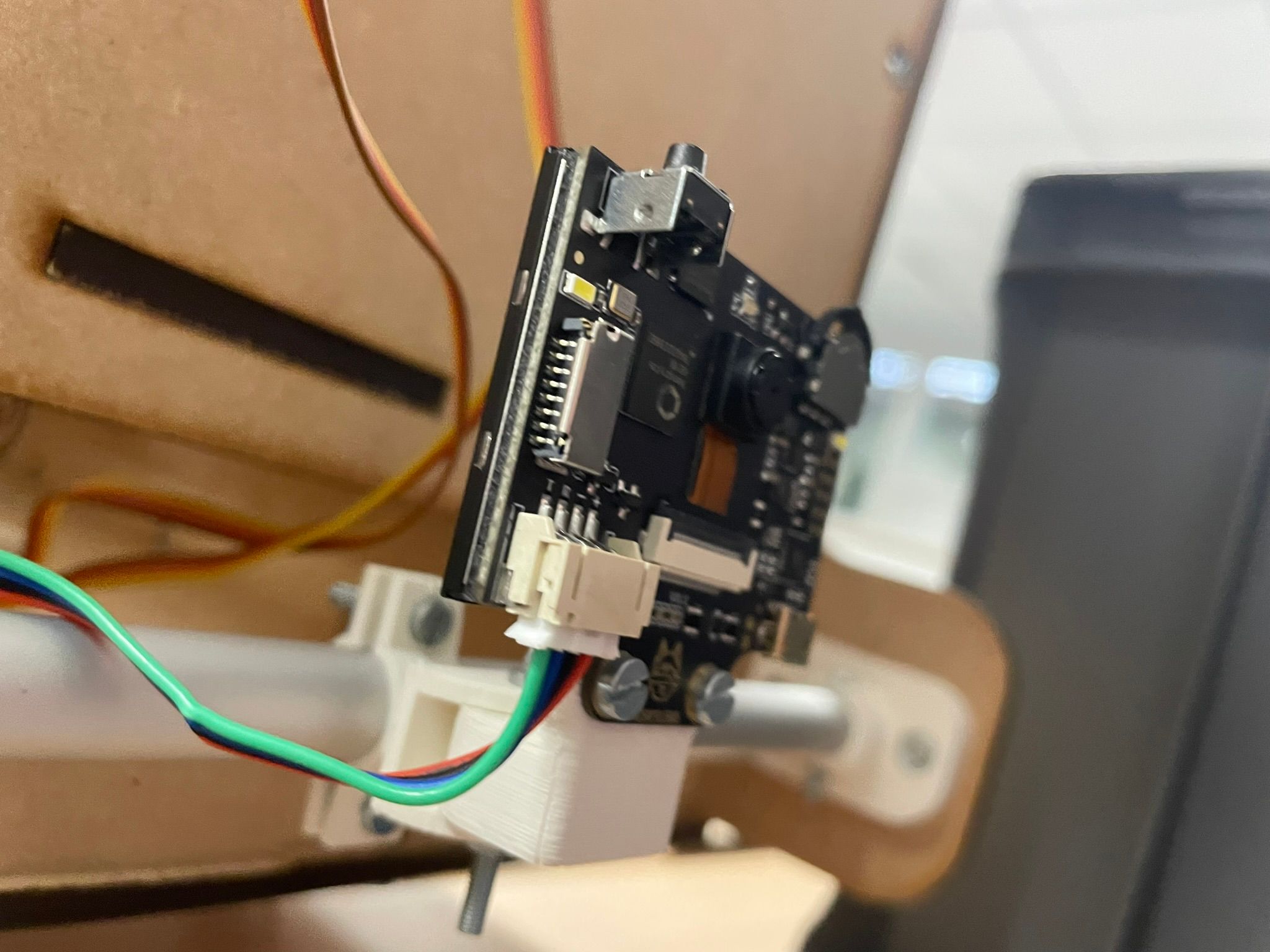

- HuskyLens camera (QR tracking)

Maxime Berlocher

- Power supply architecture

- Battery selection & sizing

- Wiring diagram & integration

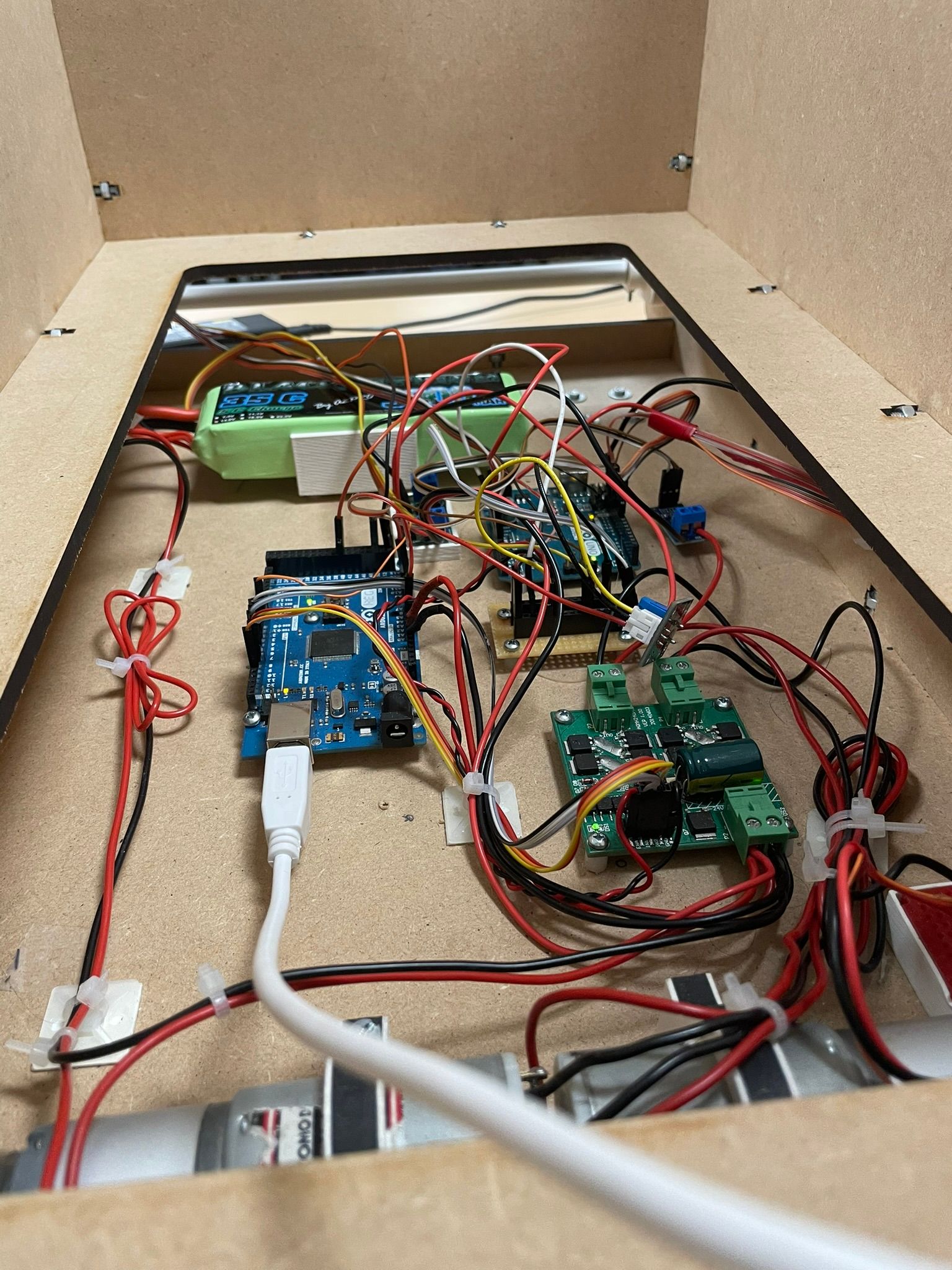

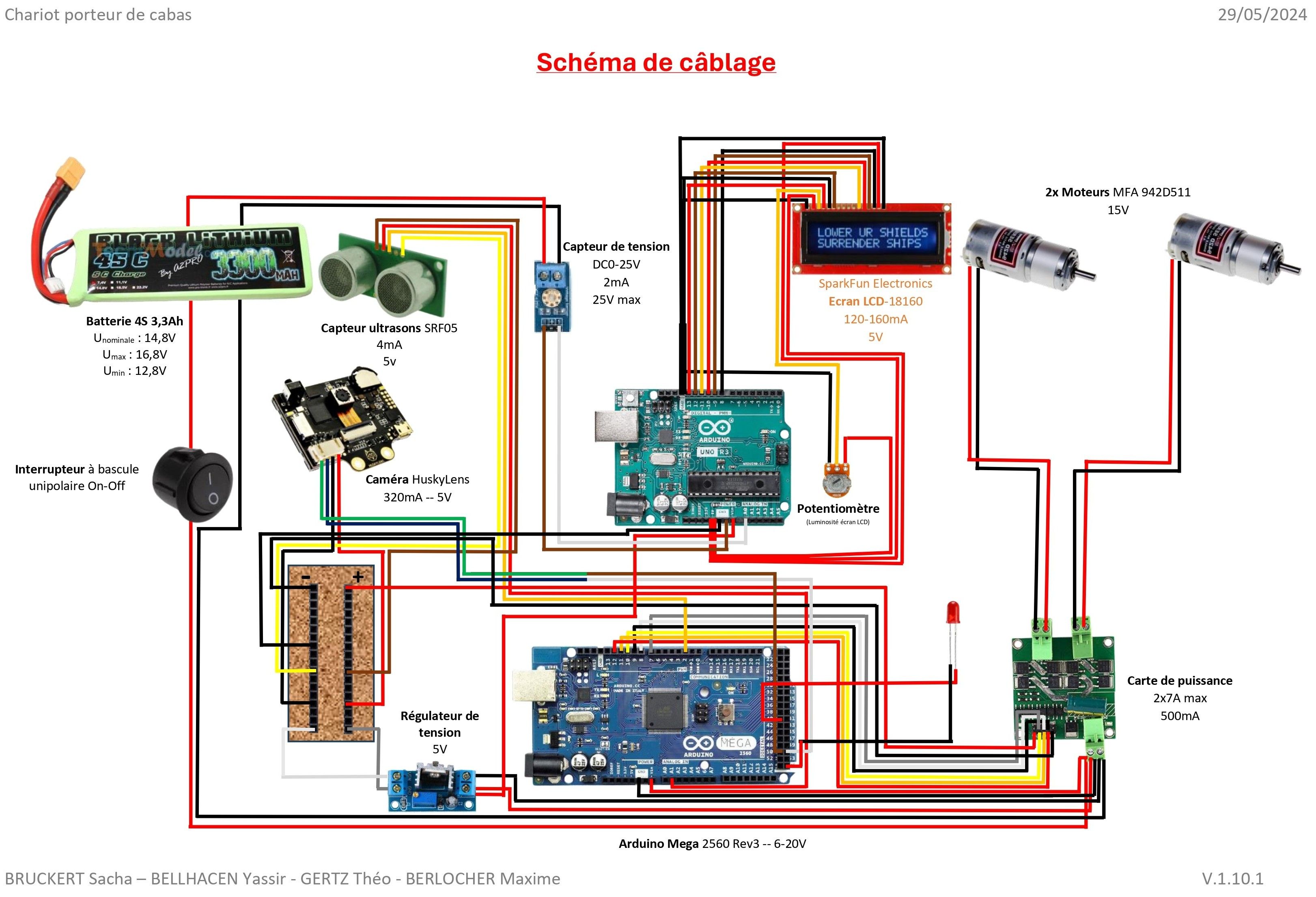

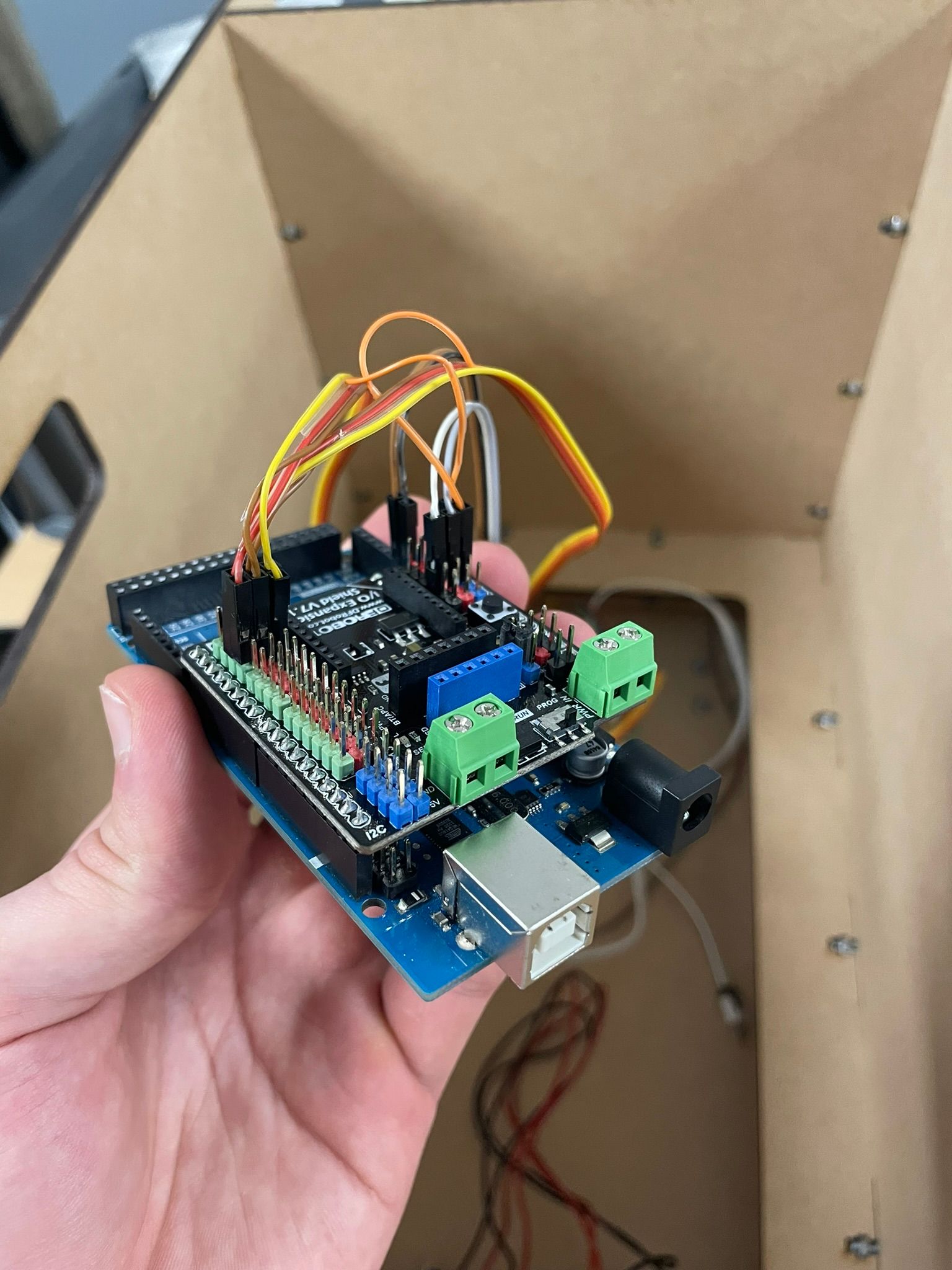

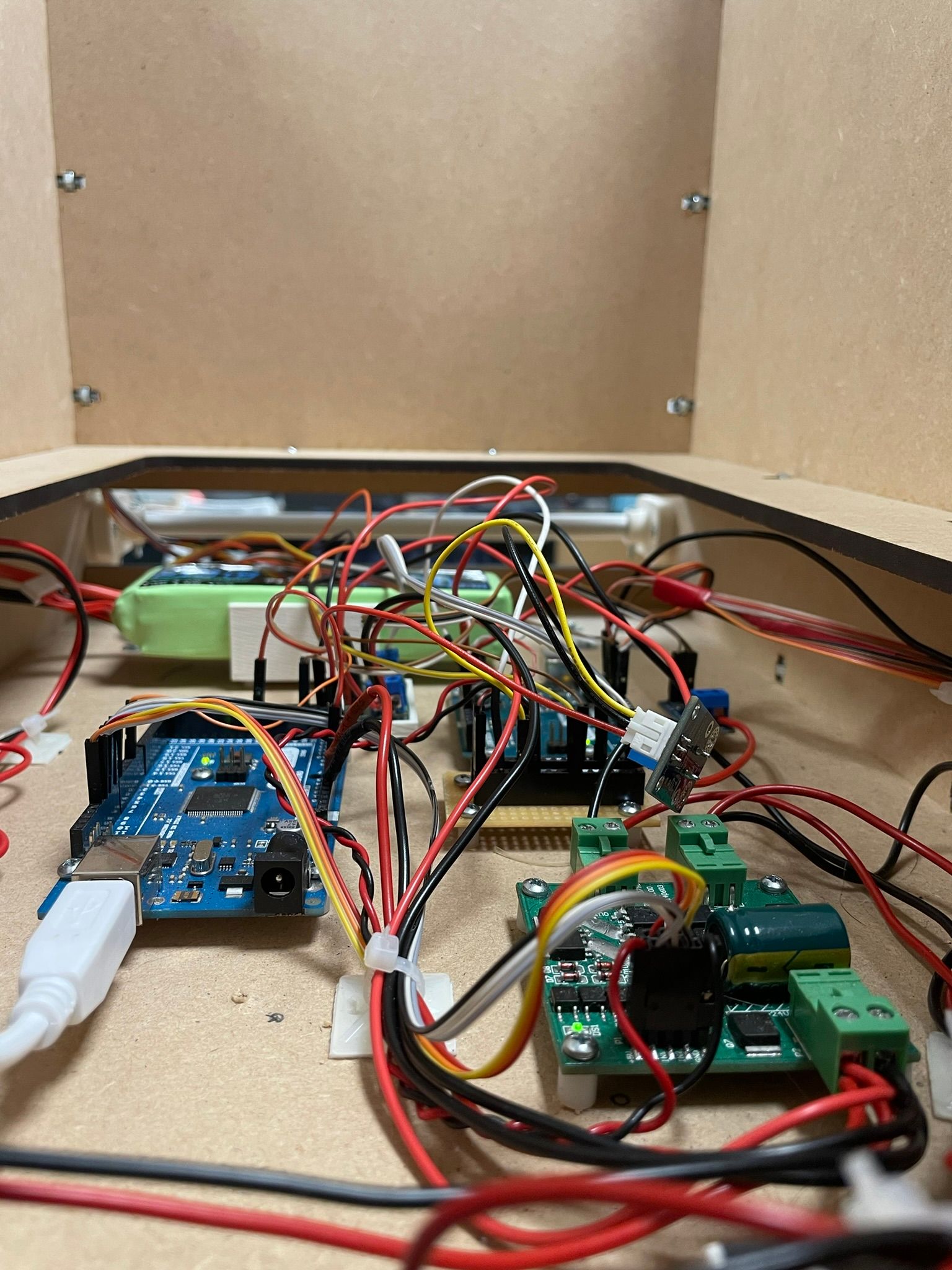

Electrical system and wiring for the complete prototype

Technical Approach

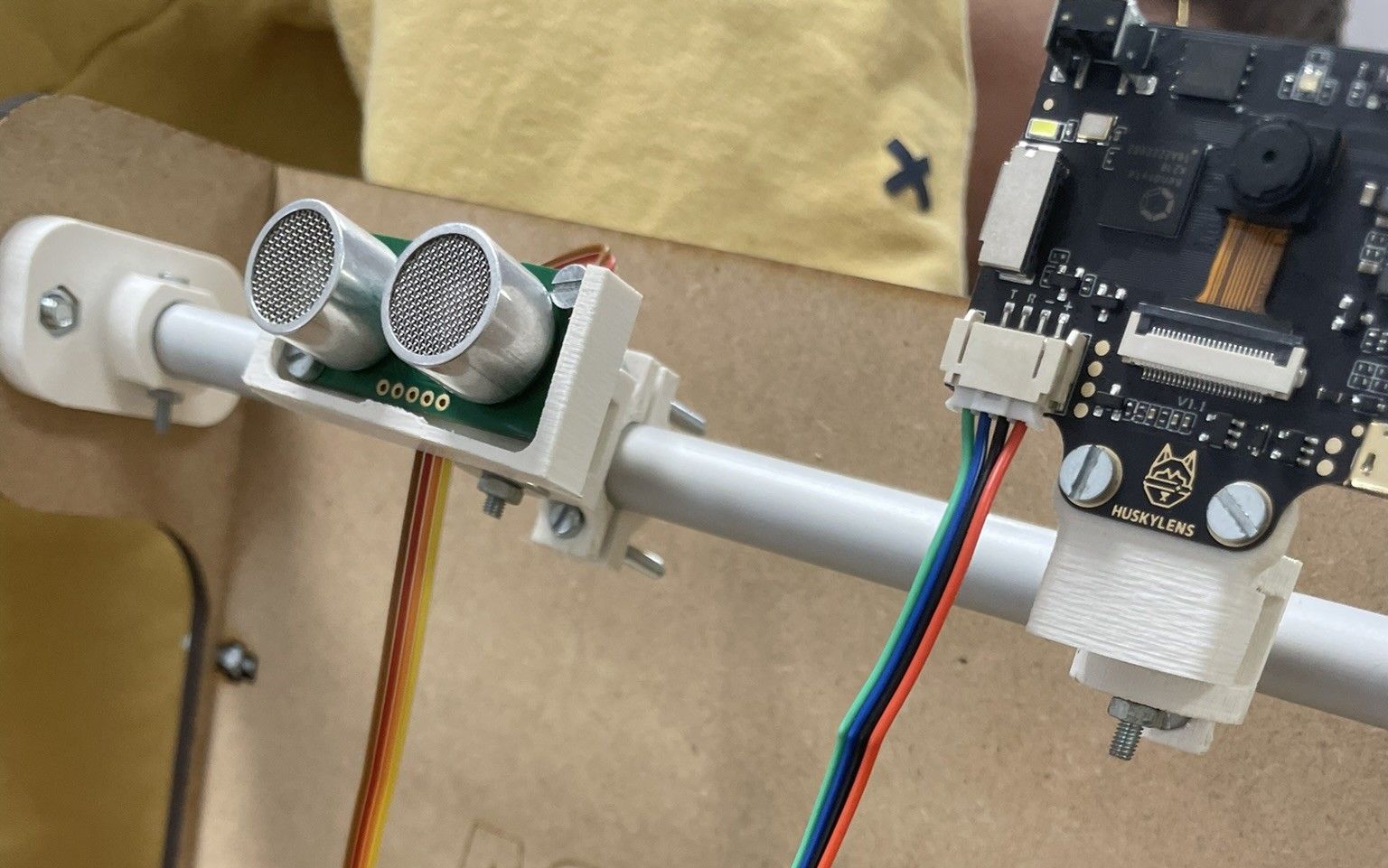

Our following strategy relied on HuskyLens camera tracking a QR code associated with the customer. For safety and comfort, we tuned the behavior to keep a short tracking distance (around 50 cm) to avoid pushing into the user.

Ultrasonic sensors were used as a safety layer to detect obstacles and reduce collision risks in dynamic aisles. Two motorized wheels provided both propulsion and steering by varying the speed of each motor (differential drive), with a front pivot caster for stability and maneuverability.

Tracking

HuskyLens + QR code follow

Following distance

≈ 50 cm (target)

Safety

Ultrasonic sensors (obstacle avoidance)

Drive base

Differential drive + front caster

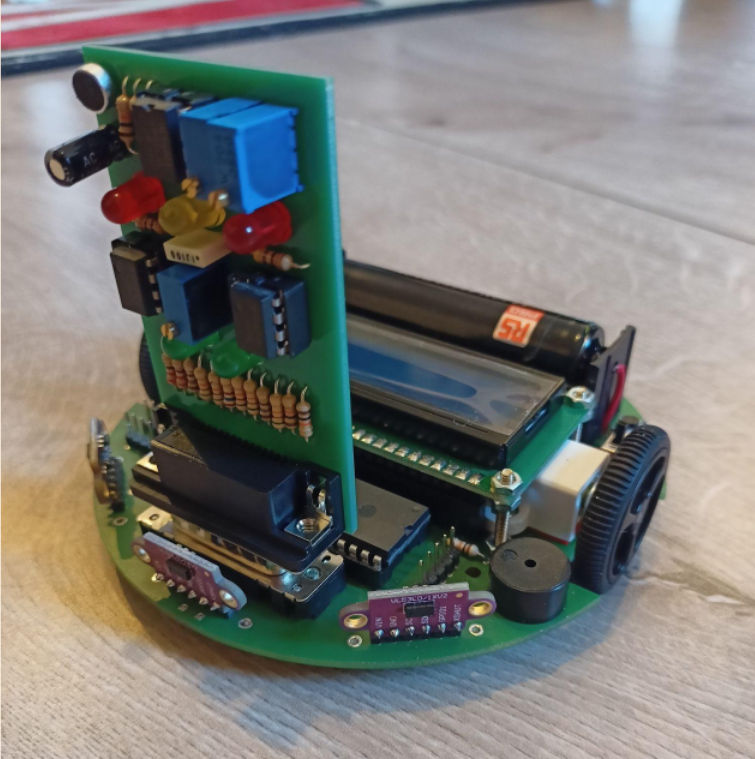

Power & Wiring (My contribution)

I designed the power architecture, selected the battery format, and produced the wiring diagram used for integration. The system was powered by a 4S lithium battery pack (≈ 12V, nominal around 14.6V).

Power design priorities

Stable supply under load, safe wiring practices, clear distribution, and easy maintenance during iterative prototyping and testing.

- Battery selection & sizing for a mobile prototype

- Power distribution and wiring organization

- Integration support during assembly and testing

Wiring diagram of the complete system

Development Process (5 months)

Phase 1 — Need & constraints

Define user pain points, safety constraints, and realistic supermarket scenarios.

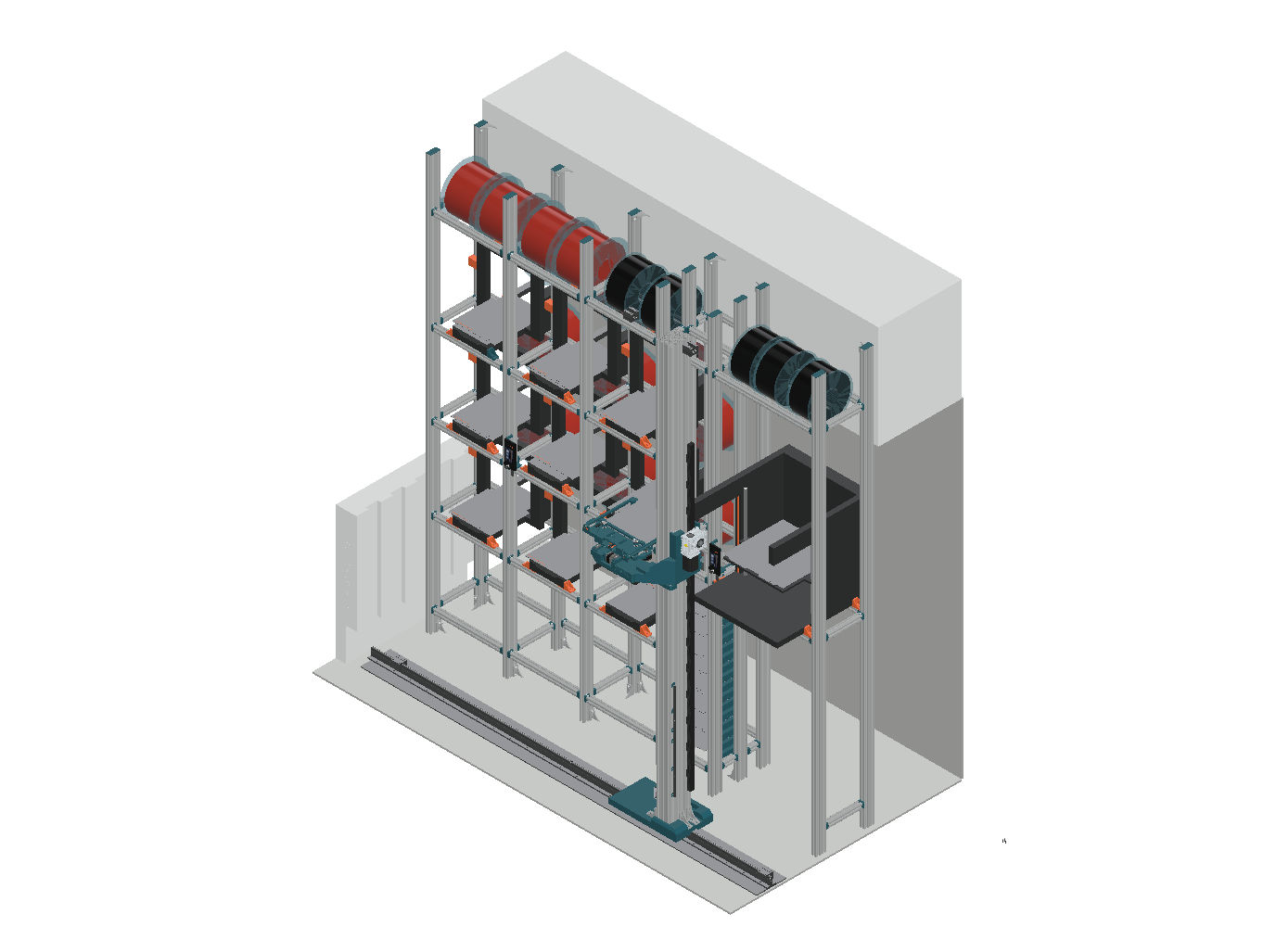

Phase 2 — Architecture & simulations

Model behaviors and validate early assumptions with Scilab before building.

Phase 3 — Prototyping & fabrication

Iterations using 3D printers, laser cutters, and soldering tools to integrate electronics and mechanics.

Phase 4 — Integration & testing

Validate tracking, obstacle avoidance, power stability, and user interface feedback.

Gallery

Replace each image path with your real photos (prototype, workshop, wiring, sensors, tests).

Key Takeaways

- Designing for accessibility requires clear safety constraints and simple interaction flows.

- Layered perception (camera tracking + obstacle sensors) improves robustness in real environments.

- Power architecture and wiring quality are critical for reliability during long test sessions.

- Iterative prototyping (3D print / laser cut) accelerated mechanical and integration improvements.