Family project • Started Nov 2022 • In progress

AIS — Automated Plate Swapping for a 3D Print Farm

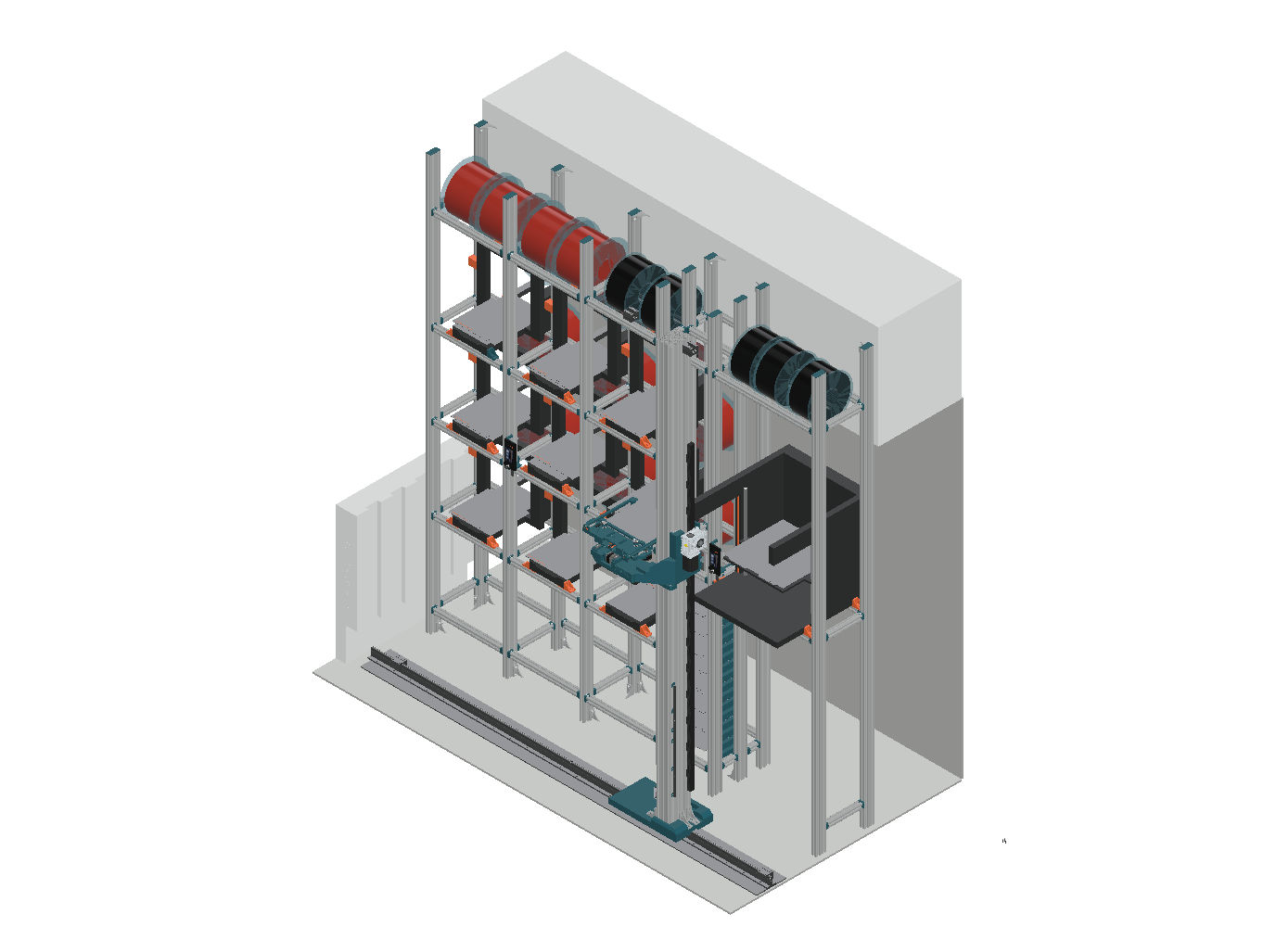

AIS is our in-house automation project inspired by the Prusa Pro Automated Farm System (AFS): a robotic setup designed to swap full build plates for empty ones, so a group of printers can run longer during nights and low-attention periods.

Origin

The project started in November 2022 after we saw the Prusa Pro AFS concept at Formnext in Frankfurt. Prusa’s idea is simple and powerful: reduce downtime and push print farm utilization closer to 24/7 production through automation and management software.

Why it matters for us

At home we operate around ten printers. Our internal tracking showed that despite spending time restarting prints, real printing happens only ~20% of the time. A plate-swapping workflow is a direct way to reduce idle time.

- Goal: keep printers productive during nights and low-attention hours

- Constraint: robust mechanics + safe handling of hot/used plates

- Approach: modular structure + robotic arm + sensors + reliable power distribution

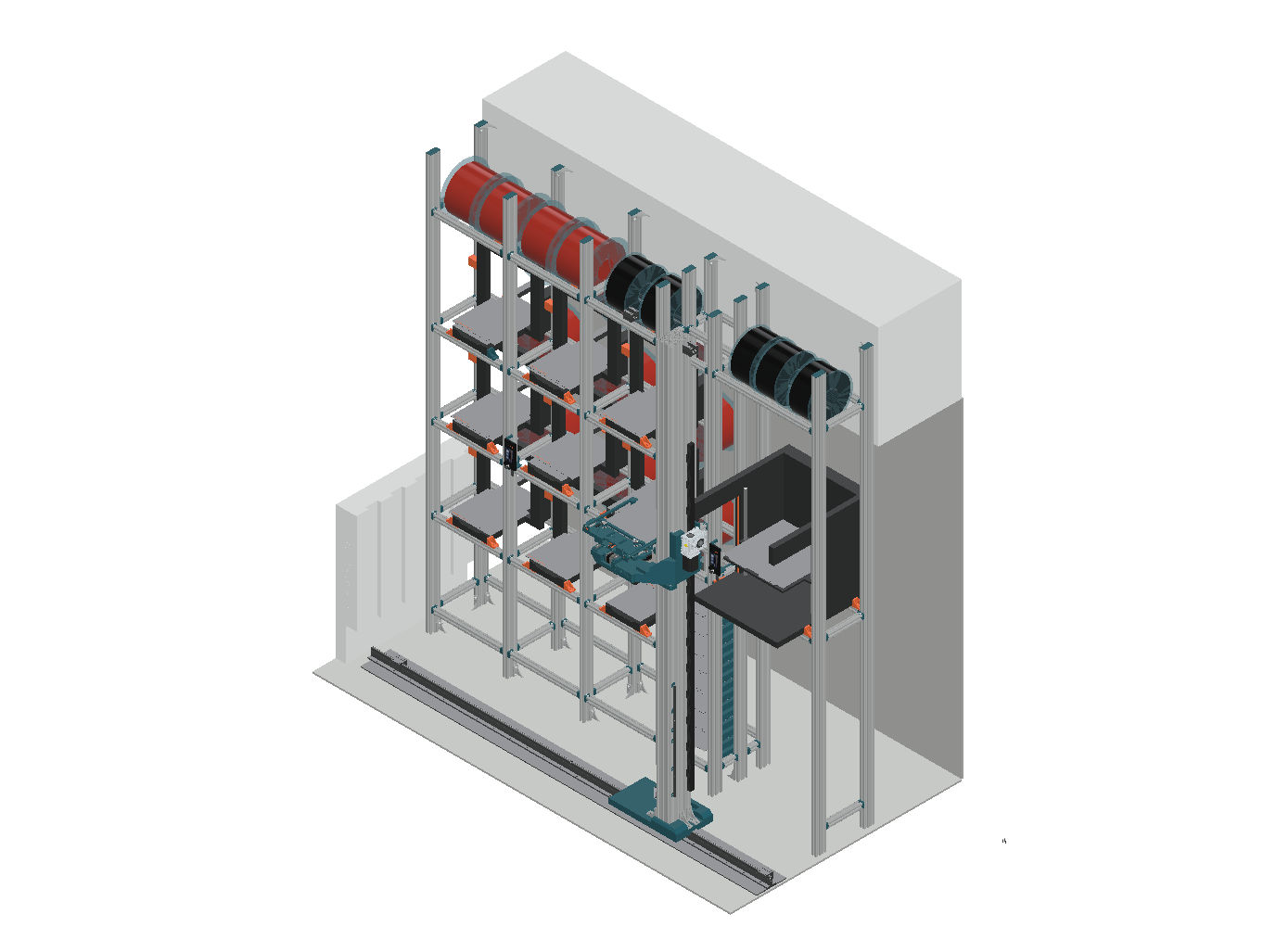

Frame structure — aluminum extrusion used to build a rigid, modular support system

Team & Responsibilities

Frédéric Berlocher

- Mechanical design in Fusion 360

- Procurement and supplier coordination

- 3D printing pipeline and mechanical assembly

Maxime Berlocher

- Power supply architecture & sizing

- Control strategy and electronics integration

- Programming foundations & system validation plan

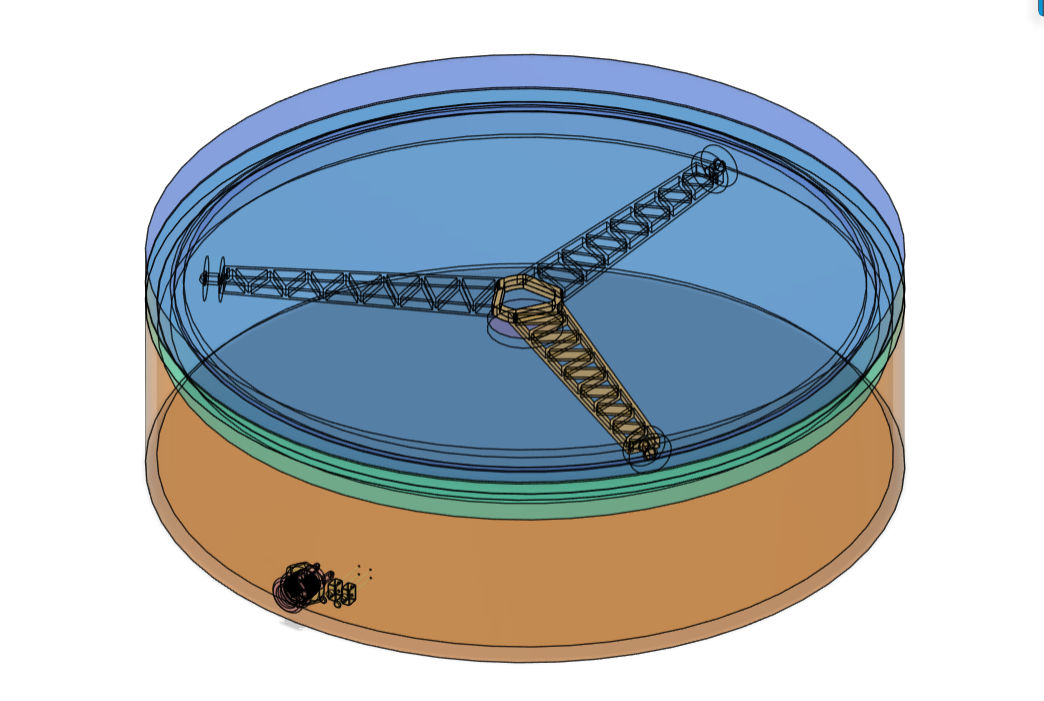

Early concept — Fusion 360 design work for the printer rack and robotic plate-handling arm

Mechanical Architecture

The first phase focused on the foundation: a rigid frame to support printers and an arm concept capable of handling build plates consistently. The structure combines metal parts for stiffness and 3D printed joints/brackets to adapt and iterate quickly.

Structure

Aluminum extrusion + custom connectors

Arm parts

Mostly 3D printed (PETG)

Iteration

Fast redesign cycles from CAD to prints

Assembly

Mixed metal + printed interfaces

Electrical & Control (My focus)

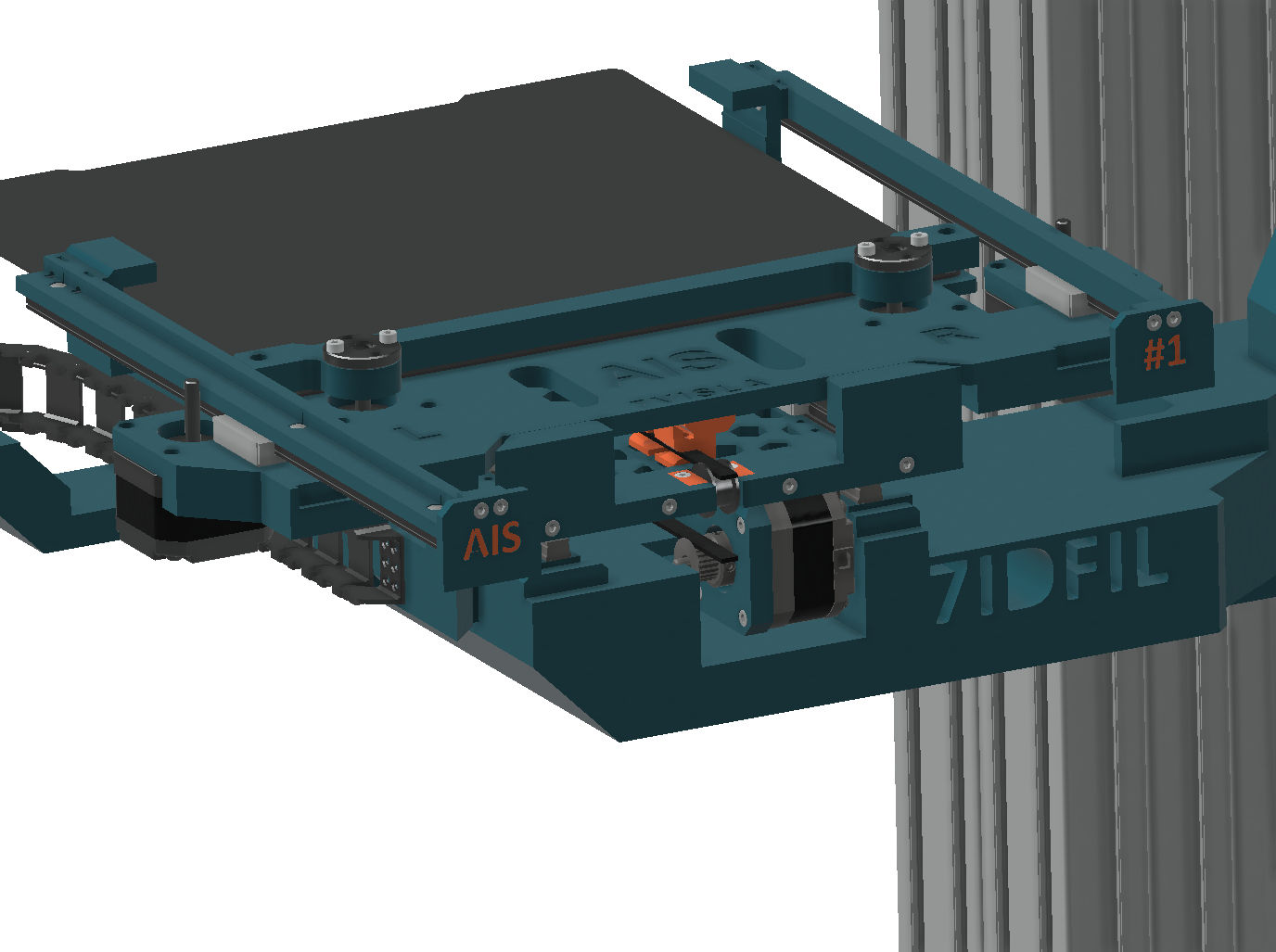

After the mechanical base, we moved to the technical specification of the robotic arm: what we want it to do, how to sense state, and how to control motion safely. At this stage, the work is mainly a structured design effort: requirements, candidate solutions, component shortlist, and integration constraints.

Engineering priorities

Reliability over speed, clear failure modes, serviceability (easy maintenance), and safe plate handling during unattended runs.

- Power distribution plan for motors, sensors and controllers

- Motion control architecture (drivers, homing, limits, calibration)

- Sensor strategy for plate detection and positioning

- Clean wiring and documentation (schematics, harnessing, labeling)

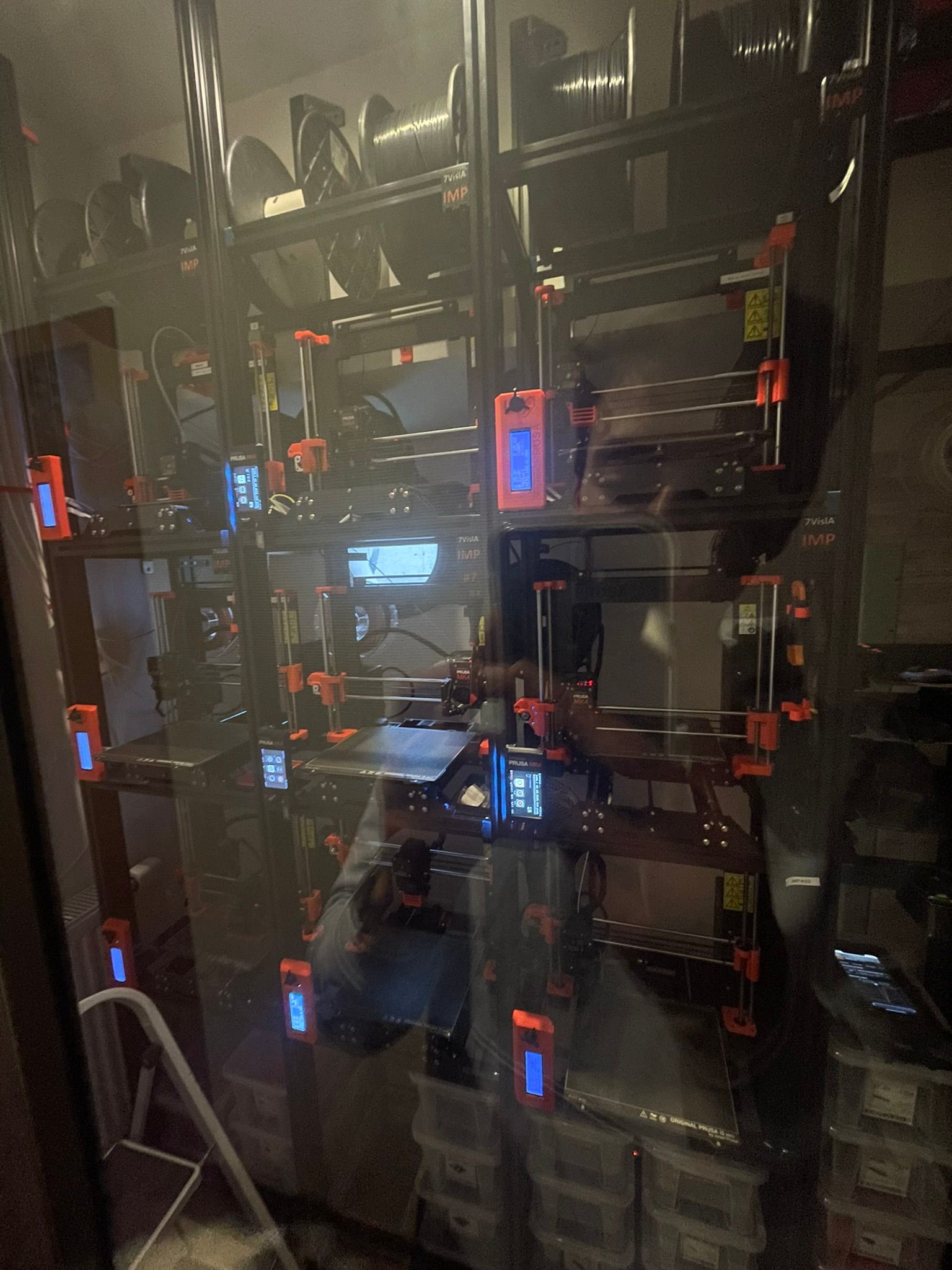

Current state — frame and mounting points assembled; next step is arm fabrication and electronics integration

Status & Next Steps

Phase 1 — Inspiration & feasibility

Observed the Prusa Pro AFS approach, translated the concept to our home print farm constraints and workflow.

Phase 2 — Mechanical design & procurement

Fusion 360 modeling, selection of aluminum extrusion, and early frame assembly using metal parts and printed connectors.

Phase 3 — System specification (current)

Requirements, component shortlist, power budget, motion architecture, sensor plan, and integration constraints.

Phase 4 — Fabrication & integration (next)

Print PETG arm parts, install motors/sensors, wire controllers, and run iterative tests (homing, repeatability, plate handling).

Gallery

Add your build photos as you progress (CAD, frame assembly, printed parts, wiring, tests).

Key Takeaways (so far)

- Print-farm productivity is often limited by handling and setup time, not by printing speed.

- Automation is only valuable if the system is serviceable and predictable under unattended operation.

- CAD and modular structures allow fast iteration without locking into a single design too early.

- Clear specs (power, sensors, motion, failure modes) reduce integration risk later.